Features

1.Compact structure and small volume with planetary transmission principle, input shaft and output shaft in the same axial line, make the type size as small as possible.

2.WB mini cycloid speed reducer using single transmission with high speed ratio and high efficiency, and can achieve the reduction ratio of 7, efficiency over 90%, if the multi-stage transmission, reduction ratio is bigger.

3.Reliable use, long life due to the main parts adopt high carbon chrome steel material, through the quenching (HRC58-62) to obtain high strength, and part of the transmission adopts rolling friction contact, so durable long service life.

4.Smooth operation, low noise cycloid pin gear meshing teeth more, overlap coefficient and balancing mechanism of parts, the vibration and noise will be limited to a minimum.

5.Reasonable design, convenient maintenance, easy to decompose the installation, the minimum number of parts and simple and smooth, make the cycloidal reducer trusted by the user.

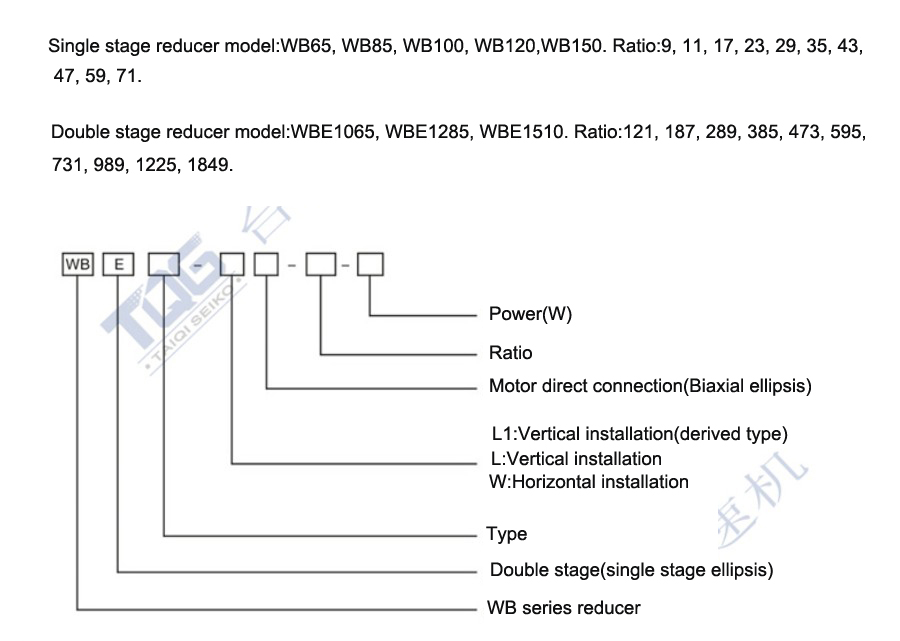

Model indication

Application

Platform lifting, working height adjustment of surface processing machine, tilt level adjusting of sliding transmission belt, working height modification of corrector, automatic opening and closing of large scale windows and doors.

Installation

Notes before installation:

1.Clean out the shaft and inspect if there is bruising or dirt on the shaft before use the gearbox.

2.Working temperature is 0~40 degree.

3.Check if the mating dimension of hole which connect to the steering gearbox meet the requirements.

4.Please change the stopper to vent plug at the highest position before use the gearbox to ensure the steering gearbox can vent the gas in the body when it running.

Installation:

1.Steering gearbox only can be mounted on flat, vibration-reducing, torsion resist supporting structure.

2. In any case, knocking belt pulley, coupler, small gear or chain wheel by hammer into the output shaft is not allowed to prevent bearing and shaft from damaging.

Operation and maintenance:

1.Please inspect if the steering gearbox is flexible after installation. Please conduct a non-load test before formal using; Add the load gradually under the condition of normal running.

2.Use the steering gearbox at exceeding rated load is forbidden.

3.Check the oil level before and during using the steering gearbox, lubricating oil was already filled into the gearbox before delivery.

Oil change rule:

First time of oil change: after 300-400 hours running. Then change the oil after every 1500-2000 hours.

The lubricating oil should be inspected every half month under the bad working condition and the occasion of high temperature, heavy dust. Please change the oil once dirt is found to keep lubricating oil clean, lengthen steering gearbox service time and increase economic benefit.

1. How to store the gearbox?

1)Keep the reducer in a clean and dry place.

2)If it will be stored outdoor or in a humid place, please put the reducer in a box and packed tightly with plastic bag to avoid the rain and external erosion. ( take measure of anti-condensation and anti-rust)

2. Cautions during operation:

1)Overload is forbidden.

2)Input speed can not exceed the proper max. Speed.

3)Please stop and check the gearbox if there are the following occurs:

Temperature rise suddenly

Abnormal big noise in a sudden

Speed became unstable suddenly

3.Warranty instruction:

The following cost and damages are not included in our warranty:

1)Freight cost

2)If the Reducer connect with or insert in a unit, when we dismounting or mounting on the unit and other extra action, there will be a cost.( this is not contained in the warranty)

3)The indirect damage that user lost the appliance chance or business break off due to reducer breakdown.

4)Other derivative and accompanying damages.