Features

1.The spiral commutator design service life is long, large carrying capacity, smooth transmission,low noise gear linear velocity can be as high as 40 meters/seconds, transmission efficiency is as high as 94% - 98%.

2.HD commutator spiral cone gear box body shape for regular hexahedron, able to adapt to different location of installation.

3.The commutator can realize reduction and growth of two kinds of driving mode.

4.There are seven kinds of specifications of the HD series commutator, large range of selection and the output shaft in a variety of forms, can meet the needs of a variety of occasions.

5.Arc tooth taper gear is made of high quality low carbon alloy steel, after carburizing and quenching heat treatment, and the grinding running-in, realize high precision closed transmission of hard-toothed surface.

Details:

1.Case: High rigidity FC-25 cast iron

2.Gears: The material is high quality high purity steel alloy 20CrMnTiH with carburizing and quenching treatment and grinding process.

3.Main shaft: Adopt steel alloy to temper, high hanging load capacity

4.Bearing: Heavy load capacity taper roller bearing

5.Oil seal: The oil seal with double sealing lips, it has ability of dust proof and oil leak proof.

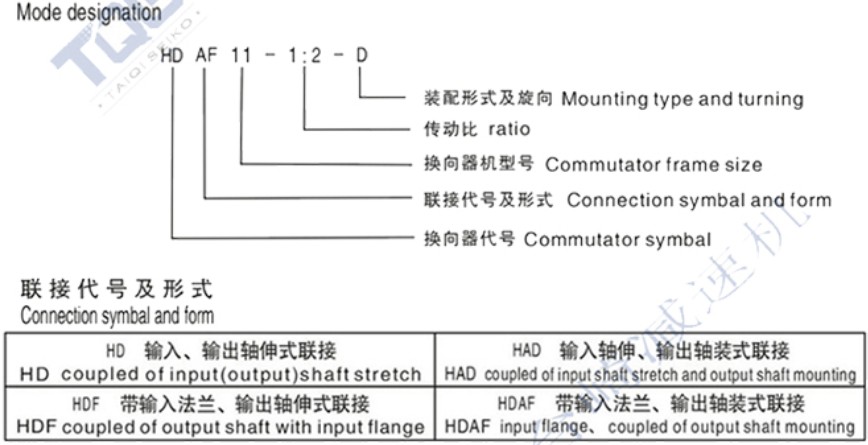

Model indication

Application

Used for side by side transmission, lifting equipment ( left and right outputting by one reducer, after steering, realize synchronous lifting), Mechanical parking system ( one reducer drive left and right chain wheel run synchronously), Game machine ( one vertical shaft inputting, double horizontal shafts run reversely), Packing machine.

Installation

Notes before installation:

1.Clean out the shaft and inspect if there is bruising or dirt on the shaft before use the gearbox.

2.Working temperature is 0~40 degree.

3.Check if the mating dimension of hole which connect to the steering gearbox meet the requirements.

4.Please change the stopper to vent plug at the highest position before use the gearbox to ensure the steering gearbox can vent the gas in the body when it running.

Installation:

1.Steering gearbox only can be mounted on flat, vibration-reducing, torsion resist supporting structure.

2. In any case, knocking belt pulley, coupler, small gear or chain wheel by hammer into the output shaft is not allowed to prevent bearing and shaft from damaging.

Operation and maintenance:

1.Please inspect if the steering gearbox is flexible after installation. Please conduct a non-load test before formal using; Add the load gradually under the condition of normal running.

2.Use the steering gearbox at exceeding rated load is forbidden.

3.Check the oil level before and during using the steering gearbox, lubricating oil was already filled into the gearbox before delivery.

Oil change rule:

First time of oil change: after 300-400 hours running. Then change the oil after every 1500-2000 hours.

The lubricating oil should be inspected every half month under the bad working condition and the occasion of high temperature, heavy dust. Please change the oil once dirt is found to keep lubricating oil clean, lengthen steering gearbox service time and increase economic benefit.

1. How to store the gearbox?

1)Keep the reducer in a clean and dry place.

2)If it will be stored outdoor or in a humid place, please put the reducer in a box and packed tightly with plastic bag to avoid the rain and external erosion. ( take measure of anti-condensation and anti-rust)

2. Cautions during operation:

1)Overload is forbidden.

2)Input speed can not exceed the proper max. Speed.

3)Please stop and check the gearbox if there are the following occurs:

Temperature rise suddenly

Abnormal big noise in a sudden

Speed became unstable suddenly

3.Warranty instruction:

The following cost and damages are not included in our warranty:

1)Freight cost

2)If the Reducer connect with or insert in a unit, when we dismounting or mounting on the unit and other extra action, there will be a cost.( this is not contained in the warranty)

3)The indirect damage that user lost the appliance chance or business break off due to reducer breakdown.

4)Other derivative and accompanying damages.