Features

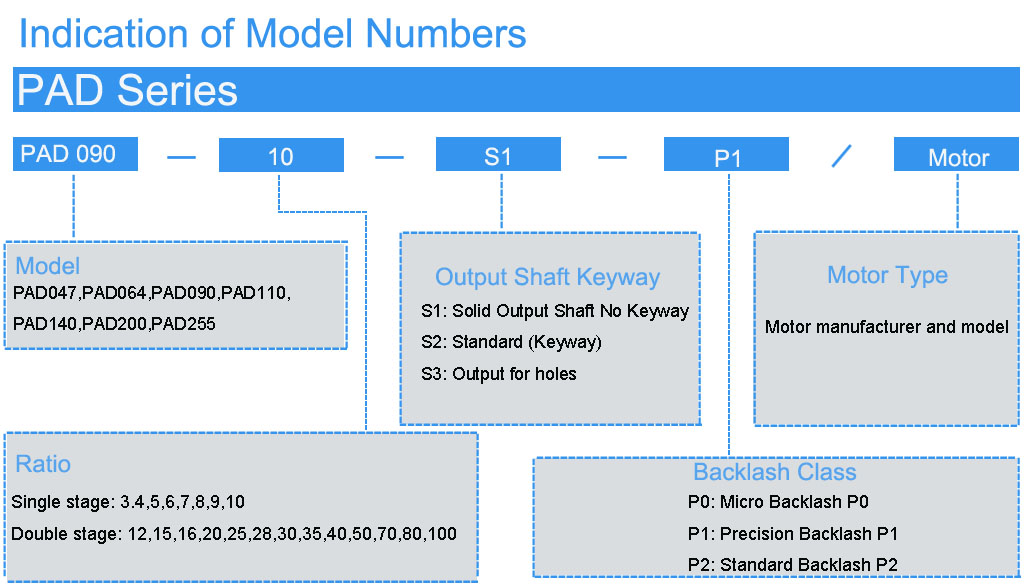

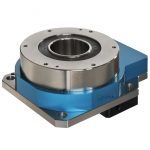

PAD series is a hollow shaft planetary gearbox. It can be fast connected to any motor output shaft.The rotating output flange replaces the traditional output shaft, giving it a unique power transfer solution .

The PAD planetary gear on the shaft is supported by both ends of the full needle roller bearing, which enhances the torsion stiffness.The output shaft of PAD planetary gearbox is supported by two taper roller bearings for greater carrying capacity

The PAD hollow shaft planetary gearbox is with highest torsional stiffness, tilting moment and compactness.Backlash of PAD planetary gearbox can be to 1 arcmin.With the excellent positioning performance and high torque,PAD planetary gearbox is specially suitable for the motion occasion of high positioning precision, dynamic cyclic operations and compact solutions for motion control, automation, CNC machines and robotic.PAD planetary reducers have been used by famous manufacturing companies, such as Samsung, Canon and LG,etc.

Input size of PAD planetary gearbox is customizable,it can replace of similar models from other factories.So it is suitable for all kinds of servo motor and stepper motor.PAD inline planetary gearbox have various of speed reduction from 4-100.

PAD series planetary gearbox is with round output flange and output hollow shaft.

PAD planetary gearbox has the features of:

(1)High precision

Standard backlash is 3 arc-min,ideal for precision control

(2)High rigidity&torque

High rigidity & torque were achieved by uncaged needle roller bearings.

(3)High load capacity

Adopting taper roller bearing for the main output shaft to increase radial and axial load.

(4)Adapter-bushing connection

Can be attached to any motor all over the world.

(5)No grease leakage

Perfect solution using high viscosity anti-separation grease.

(6)Maintenance-free

No need to replace the grease for the life of the unit.Can be attached in any position.

Model Selection

How to choose a correct PAD model?

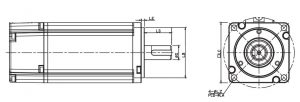

(1)Check your motor drawing,offer the below dimensions:

φS:shaft diameter

LB:motor convex circle diameter

φLA:motor flange PCD

LS:shaft length

LE:motor convex circle thickness

φLZ:motor mounting hole size

Then compare these dimensions to our gearbox dimensions(refer to our catalogue)you can probably know the frame size of our gearbox.

(2)What's the ratio or output speed you need?Check if the gearbox output torque>motor torque*ratio

Ratio i=Input speed(RPM)/gearbox output speed(RPM)

Motor torque(N.m)=9550*motor power(KW)/motor speed(RPM)

(3)Make sure the precision(backlash)you need,then you can know which type of gearbox you need.

(4)If you don't have the information above,please send us the servo motor dimension drawing for model selection or advise the specific servo motor model number,then we are pleasure to help you choose a suitable model.

After determine the above, you can choose a smallest volume gearbox to save cost.

If you have special requirement for the precision, please clarify.

Parameters

| Model No. | Unit | Stage | Ratio | PAD047 | PAD064 | PAD090 | PAD110 | PAD140 | PAD200 | PAD255 |

| Rated Output Torque | Nm | 1 | 4 | 19 | 50 | 133 | 278 | 555 | 1050 | 1700 |

| 5 | 22 | 60 | 160 | 330 | 650 | 1200 | 2000 | |||

| 7 | 19 | 50 | 140 | 300 | 550 | 1100 | 1800 | |||

| 10 | 14 | 40 | 100 | 230 | 450 | 900 | 1500 | |||

| 2 | 20 | 19 | 50 | 133 | 278 | 555 | 1050 | 1700 | ||

| 25 | 22 | 60 | 160 | 330 | 650 | 1200 | 2000 | |||

| 35 | 19 | 50 | 140 | 300 | 550 | 1100 | 1800 | |||

| 40 | 19 | 45 | 120 | 260 | 500 | 1000 | 1600 | |||

| 50 | 22 | 60 | 160 | 330 | 650 | 1200 | 2000 | |||

| 70 | 19 | 50 | 140 | 300 | 550 | 1100 | 1800 | |||

| 100 | 14 | 40 | 100 | 230 | 450 | 900 | 1500 | |||

| Max. Output Torque | Nm | 1,2 | 4-100 | 3 Times of Normal Output Torque | ||||||

| Rated Input Speed | Rpm | 1,2 | 4-100 | 5000 | 5000 | 4000 | 4000 | 3000 | 3000 | 2000 |

| Max. Input Speed | Rpm | 1,2 | 4-100 | 10000 | 10000 | 8000 | 8000 | 6000 | 6000 | 4000 |

| Micro Backlash P0 | Arcmin | 1 | 4-10 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

| 2 | 12-100 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| Precision Backlash P1 | Arcmin | 1 | 4-10 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 |

| 2 | 20-100 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ||

| Standard Backlash P2 | Arcmin | 1 | 3-10 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 |

| 2 | 20-100 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ||

| Torsional Rigidity | Nm/arcmin | 1,2 | 3-100 | 8 | 13 | 30 | 80 | 150 | 450 | 1010 |

| Max. Axial Force | N | 1,2 | 3-100 | 990 | 1050 | 2850 | 2990 | 10590 | 16660 | 29430 |

| Service Life | Hr | 1,2 | 3-100 | 22000hrs | ||||||

| Efficiency | % | 1 | 3-10 | ≥97% | ||||||

| 2 | 20-100 | ≥94% | ||||||||

| Weight | Kg | 1 | 4-10 | 0.7 | 1.3 | 3.2 | 5.8 | 12.3 | 33 | 57.9 |

| 2 | 20-100 | 1 | 1.5 | 4.1 | 7.6 | 16.8 | 38 | 72.6 | ||

| Operating Temperature | ℃ | 1,2 | 3-100 | (-15℃~+90℃) | ||||||

| Lubrication | 1,2 | 3-100 | Synthetic Grease | |||||||

| Protection Class | 1,2 | 3-100 | IP65 | |||||||

| Mounting Position | 1,2 | 3-100 | Any Direction | |||||||

| Noise Level | dB(A) | 1,2 | 3-100 | ≤56 | ≤58 | ≤60 | ≤63 | ≤65 | ≤67 | ≤70 |

| Model No. | Unit | Stage | Ratio | PAD047 | PAD064 | PAD090 | PAD110 | PAD140 | PAD200 | PAD255 |

| Rated Output Torque | Nm | 1 | 4 | 19 | 50 | 133 | 278 | 555 | 1050 | 1700 |

| 5 | 22 | 60 | 160 | 330 | 650 | 1200 | 2000 | |||

| 7 | 19 | 50 | 140 | 300 | 550 | 1100 | 1800 | |||

| 10 | 14 | 40 | 100 | 230 | 450 | 900 | 1500 | |||

| 2 | 20 | 19 | 50 | 133 | 278 | 555 | 1050 | 1700 | ||

| 25 | 22 | 60 | 160 | 330 | 650 | 1200 | 2000 | |||

| 35 | 19 | 50 | 140 | 300 | 550 | 1100 | 1800 | |||

| 40 | 19 | 45 | 120 | 260 | 500 | 1000 | 1600 | |||

| 50 | 22 | 60 | 160 | 330 | 650 | 1200 | 2000 | |||

| 70 | 19 | 50 | 140 | 300 | 550 | 1100 | 1800 | |||

| 100 | 14 | 40 | 100 | 230 | 450 | 900 | 1500 | |||

| Max. Output Torque | Nm | 1,2 | 4-100 | 3 Times of Normal Output Torque | ||||||

| Rated Input Speed | Rpm | 1,2 | 4-100 | 5000 | 5000 | 4000 | 4000 | 3000 | 3000 | 2000 |

| Max. Input Speed | Rpm | 1,2 | 4-100 | 10000 | 10000 | 8000 | 8000 | 6000 | 6000 | 4000 |

| Micro Backlash P0 | Arcmin | 1 | 4-10 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

| 2 | 12-100 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| Precision Backlash P1 | Arcmin | 1 | 4-10 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 |

| 2 | 20-100 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ||

| Standard Backlash P2 | Arcmin | 1 | 3-10 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 |

| 2 | 20-100 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ||

| Torsional Rigidity | Nm/arcmin | 1,2 | 3-100 | 8 | 13 | 30 | 80 | 150 | 450 | 1010 |

| Max. Axial Force | N | 1,2 | 3-100 | 990 | 1050 | 2850 | 2990 | 10590 | 16660 | 29430 |

| Service Life | Hr | 1,2 | 3-100 | 22000hrs | ||||||

| Efficiency | % | 1 | 3-10 | ≥97% | ||||||

| 2 | 20-100 | ≥94% | ||||||||

| Weight | Kg | 1 | 4-10 | 0.7 | 1.3 | 3.2 | 5.8 | 12.3 | 33 | 57.9 |

| 2 | 20-100 | 1 | 1.5 | 4.1 | 7.6 | 16.8 | 38 | 72.6 | ||

| Operating Temperature | ℃ | 1,2 | 3-100 | (-15℃~+90℃) | ||||||

| Lubrication | 1,2 | 3-100 | Synthetic Grease | |||||||

| Protection Class | 1,2 | 3-100 | IP65 | |||||||

| Mounting Position | 1,2 | 3-100 | Any Direction | |||||||

| Noise Level | dB(A) | 1,2 | 3-100 | ≤56 | ≤58 | ≤60 | ≤63 | ≤65 | ≤67 | ≤70 |

Moment of Inertia

| Model No. | Unit | Stage | Ratio | PAD047 | PAD064 | PAD090 | PAD110 | PAD140 | PAD200 | PAD255 |

| Moment of Inertia | kg.cm2 | 1 | 4 | 0.03 | 0.14 | 0.48 | 2.74 | 7.54 | 23.67 | 54.37 |

| 5 | 0.03 | 0.13 | 0.47 | 2.71 | 7.42 | 23.29 | 53.27 | |||

| 7 | 0.03 | 0.13 | 0.45 | 2.62 | 7.14 | 22.48 | 50.97 | |||

| 10 | 0.03 | 0.13 | 0.44 | 2.57 | 7.03 | 22.51 | 50.56 | |||

| 2 | 12-40 | 0.03 | 0.03 | 0.13 | 0.47 | 2.71 | 7.42 | 23.29 | ||

| 50-100 | 0.03 | 0.03 | 0.13 | 0.44 | 2.57 | 7.03 | 22.51 |

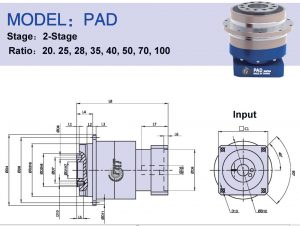

Dimensions

Reducer Dimensions:

(1) Single stage(Ratio: 4, 5, 7, 10)

Unit:mm

| Size | PAD047-L1 | PAD064-L1 | PAD090-L1 | PAD110-L1 | PAD140-L1 | PAD200-L1 | PAD255-L1 |

| D1 | 12 | 20 | 31.5 | 40 | 50 | 80 | 100 |

| D2 | 28 | 40 | 63 | 80 | 100 | 160 | 180 |

| D3 | 47 | 64 | 90 | 110 | 140 | 200 | 255 |

| D4 | 72 | 86 | 118 | 145 | 179 | 247 | 300 |

| D5 | ≤11/≤12 | 11(8-14) | 19(14-22) | 24(22-28) | 24(24-48) | 35(35-48) | 48(48-55) |

| D6 | 30 | 30(30-50) | 50(50-110) | 110 | 110(110-114.3) | 114.3(114.3-200) | 200 |

| D7 | 20 | 31.5 | 50 | 63 | 80 | 125 | 140 |

| D8 | 67 | 79 | 109 | 135 | 168 | 233 | 280 |

| D9 | Φ3 | Φ5XDep.8 | Φ6XDep.7 | Φ6XDep.7 | Φ8XDep.7 | Φ10XDep.10 | Φ12XDep.10 |

| D10 | 4-M3 | 7-M5XDep.8 | 8-M6XDep.12 | 11-M6XDep.12 | 11-M8XDep.17 | 11-M10XDep.20 | 12-M16XDep.25 |

| D11 | 8-Φ3.4 | 8-Φ4.5 | 8-Φ5.5 | 8-Φ5.5 | 12-Φ6.6 | 12-Φ9 | 16-Φ13.5 |

| D12 | 46 | 45(45-70) | 70(70-145) | 145 | 145(145-200) | 200(200-235) | 235 |

| D13 | M4 | M4-M5 | M5-M8 | M8 | M8-M12 | M12 | M12 |

| L1 | 3 | 3 | 6 | 6 | 6 | 8 | 12 |

| L2 | 7 | 7 | 10 | 10 | 14.5 | 15 | 21.5 |

| L3 | 4 | 4 | 7 | 8 | 10 | 12 | 18 |

| L4 | 19.5 | 19.5 | 30 | 29 | 38 | 50 | 66 |

| L5 | 4 | 8 | 12 | 13 | 12 | 16 | 20.0 |

| L6 | 3.5 | 4~5 | 5~10 | 10 | 6~8 | 6~10 | 10 |

| L7 | 30 | 28(28-34) | 32(32-59) | 60 | 73(73-115) | 88(88-117) | 119.5 |

| L8 | 70 | 80.5-87 | 97(97-120) | 142 | 159(159-201) | 196(196-229) | 255 |

| C1 | 48 | 60(40-60) | 90(60-130) | 130 | 130(130-180) | 180(180-220) | 220 |

Note 1:Inside of ()is the optional range of sizes,outside of ()is the standard sizes.

Note 2:The reducer output shaft size and length can be customized for customers.

Note 3:Input sizes can be subject to changed according to kinds of servo motor or stepper motor size.

(2) Double stage(Ratio: 15,20,25,30,35,40,50,70,100)

unit:mm

| Size | PAD047-L2 | PAD064-L2 | PAD090-L2 | PAD110-L2 | PAD140-L2 | PAD200-L2 | PAD255-L2 |

| D1 | 12 | 20 | 31.5 | 40 | 50 | 80 | 100 |

| D2 | 28 | 40 | 63 | 80 | 100 | 160 | 180 |

| D3 | 47 | 64 | 90 | 110 | 140 | 200 | 255 |

| D4 | 72 | 86 | 118 | 145 | 179 | 247 | 300 |

| D5 | ≤11/≤12 | 11(8-14) | 19(14-22) | 19(22-28) | 19(19-38) | 35(24-48) | 38(38-55) |

| D6 | 30 | 30(30-50) | 50(50-110) | 70(70-110) | 70(70-114.3) | 110(110-200) | 114.3(114.3-200) |

| D7 | 20 | 31.5 | 50 | 63 | 80 | 125 | 140 |

| D8 | 67 | 79 | 109 | 135 | 168 | 233 | 280 |

| D9 | Φ3 | Φ5XDep.8 | Φ6XDep.7 | Φ6XDep.7 | Φ8XDep.7 | Φ10XDep.10 | Φ12XDep.10 |

| D10 | 4-M3 | 7-M5XDep.8 | 8-M6XDep.12 | 11-M6XDep.12 | 11-M8XDep.17 | 11-M10XDep.20 | 12-M16XDep.25 |

| D11 | 8-Φ3.4 | 8-Φ4.5 | 8-Φ5.5 | 8-Φ5.5 | 12-Φ6.6 | 12-Φ9 | 16-Φ13.5 |

| D12 | 46 | 45(45-70) | 70(70-145) | 90(90-145) | 90(90-200) | 145(145-235) | 200(200-235) |

| D13 | M4 | M4-M5 | M5-M8 | M6-M8 | M5-M12 | M8-M12 | M12 |

| L1 | 3 | 3 | 6 | 6 | 6 | 8 | 12 |

| L2 | 7 | 7 | 10 | 10 | 14.5 | 15 | 20 |

| L3 | 4 | 4 | 7 | 8 | 10 | 12 | 18 |

| L4 | 19.5 | 19.5 | 30 | 29 | 38 | 50 | 66 |

| L5 | 4 | 8 | 12 | 13 | 12 | 16 | 20 |

| L6 | 3.5 | 4~5 | 5~10 | 6~10 | 6~8 | 6~10 | 6~10 |

| L7 | 30 | 28(28-34) | 34(34-59) | 43(43-60) | 65(65-85) | 73(73-117) | 73(73-117) |

| L8 | 97.5 | 103(103-110) | 123(123-139) | 150(150-176) | 195(195-211) | 292(292-336) | 306(306-322) |

| C1 | 48 | 60(40-60) | 90(60-130) | 90(90-130) | 90(90-180) | 180(130-220) | 180(180-220) |

Note 1:Inside of ()is the optional range of sizes,outside of ()is the standard sizes.

Note 2:The reducer output shaft size and length can be customized for customers.

Note 3:Input sizes can be subject to changed according to kinds of servo motor or stepper motor size.

Ouput dimensions

Download

Real Pictures