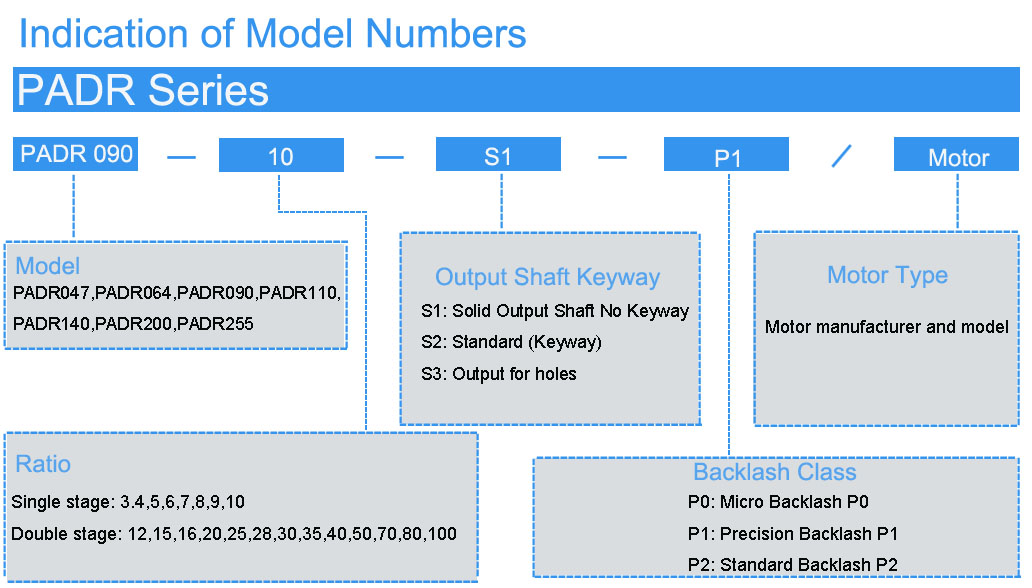

Features

PADR type is not only a hollow shaft planetary gearbox,but also a type of right angle inline gearbox.PADR series planetary gearbox use spiral bevel gears to realize the motor mounting with 90 degree bending,it can well save the installation space.The round flange output makes PADR planetary gearbox easily connect to motion system with excellent positioning performance.

The PADR planetary gear on the shaft is supported by both ends of the full needle roller bearing, which enhances the torsion stiffness.The output shaft of PADR right angle planetary gearbox is supported by two taper roller bearings for greater carrying capacity.

PADR right angle gearbox is with high torque and low backlash.If user wants helical gear planetary gearbox,you can choose P0 backlash(1 arcmin to 3 arcmin) or P1 backlash(3 arcmin to 5 arcmin).If you want spur gear,you can choose P2 backlash(6 arcmin to 8 arcmin).PADR right angle planetary gearbox has various ratios(from 3 to100) for option.PADR right angle planetary gearbox match any brands of stepper motors and servo motors due to its available customized dimensions,such as Panasonic,Mitsubishi, Yaskawa, Delta, Fuji, etc.It is widely used in manipulator, numerical control machine, cutting machine, numerical control pipe bending machine, textile machinery, painting machine, packaging machinery, medical equipment, welding machinery, printing equipment,etc.

PADR series planetary gearbox use spiral bevel gears to realize the motor mounting with 90 degree bending,and with round flange output.

Features of PADR right angle gearbox

1.Space-Save

Rectangular reducer use spiral bevel gears to make motor mounted in 90 degree bending, that is, save space.

2. High rigidity and torque

The rigidity and torque are heavily enhanced by using one-piece roller bearing.

3.Methods of connector and bush.

Can be installed on any motor all over the world.

4.No leakage of grease

Use high viscosity and non-separated grease to avoid the leakage.

5. Convenient Maintenance.

No need change the grease with the service time of reducer, install much conveniently.

Model Selection

How to choose a correct PADR model?

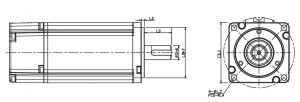

(1)Check your motor drawing,offer the below dimensions:

φS:shaft diameter

LB:motor convex circle diameter

φLA:motor flange PCD

LS:shaft length

LE:motor convex circle thickness

φLZ:motor mounting hole size

Then compare these dimensions to our gearbox dimensions(refer to our catalogue)you can probably know the frame size of our gearbox.

(2)What's the ratio or output speed you need?Check if the gearbox output torque>motor torque*ratio

Ratio i=Input speed(RPM)/gearbox output speed(RPM)

Motor torque(N.m)=9550*motor power(KW)/motor speed(RPM)

(3)Make sure the precision(backlash)you need,then you can know which type of gearbox you need.

(4)If you don't have the information above,please send us the servo motor dimension drawing for model selection or advise the specific servo motor model number,then we are pleasure to help you choose a suitable model.

After determine the above, you can choose a smallest volume gearbox to save cost.

If you have special requirement for the precision, please clarify.

Parameters

| Model No. | Unit | Stage | Ratio | PADR047 | PADR064 | PADR090 | PADR110 | PADR140 | PADR200 | PADR255 |

| Rated Output Torque | Nm | 1 | 4 | 19 | 50 | 133 | 278 | 555 | 1050 | 1700 |

| 5 | 22 | 60 | 160 | 330 | 650 | 1200 | 2000 | |||

| 7 | 19 | 50 | 140 | 300 | 550 | 1100 | 1800 | |||

| 10 | 14 | 40 | 100 | 230 | 450 | 900 | 1500 | |||

| 2 | 20 | 19 | 50 | 133 | 278 | 555 | 1050 | 1700 | ||

| 25 | 22 | 60 | 160 | 330 | 650 | 1200 | 2000 | |||

| 35 | 19 | 50 | 140 | 300 | 550 | 1100 | 1800 | |||

| 40 | 19 | 45 | 120 | 260 | 500 | 1000 | 1600 | |||

| 50 | 22 | 60 | 160 | 330 | 650 | 1200 | 2000 | |||

| 70 | 19 | 50 | 140 | 300 | 550 | 1100 | 1800 | |||

| 100 | 14 | 40 | 100 | 230 | 450 | 900 | 1500 | |||

| Max. Output Torque | Nm | 1,2 | 4-100 | 3 Times of Normal Output Torque | ||||||

| Rated Input Speed | Rpm | 1,2 | 4-100 | 5000 | 5000 | 4000 | 4000 | 3000 | 3000 | 2000 |

| Max. Input Speed | Rpm | 1,2 | 4-100 | 10000 | 10000 | 8000 | 8000 | 6000 | 6000 | 4000 |

| Micro Backlash P0 | Arcmin | 1 | 4-10 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

| 2 | 12-100 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| Precisiom Backlash P1 | Arcmin | 1 | 4-10 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 |

| 2 | 20-100 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ||

| Standard Backlash P2 | Arcmin | 1 | 4-10 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 |

| 2 | 20-100 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ||

| Torsional Rigidity | Nm/arcmin | 1,2 | 3-100 | 8 | 13 | 30 | 80 | 150 | 450 | 1010 |

| Max. Radial Force | N | 1,2 | 3-200 | 43 | 125 | 235 | 430 | 1300 | 3064 | 5900 |

| Max. Axial Force | N | 1,2 | 3-200 | 990 | 1050 | 2850 | 2990 | 10590 | 16660 | 29430 |

| Service Life | Hr | 1,2 | 3-200 | 22000hrs | ||||||

| Efficiency | % | 1 | 3-20 | ≥97% | ||||||

| 2 | 25-200 | ≥94% | ||||||||

| Weight | Kg | 1 | 3-20 | 0.7 | 1.3 | 3.2 | 5.8 | 12.3 | 33 | 57.9 |

| 2 | 25-200 | 1 | 1.5 | 4.1 | 7.6 | 16.8 | 38 | 72.6 | ||

| Operating Temperature | ℃ | 1,2 | 3-200 | (-15℃~+90℃) | ||||||

| Lubrication | 1,2 | 3-200 | Synthetic Grease | |||||||

| Protection Class | 1,2 | 3-200 | IP65 | |||||||

| Mounting Position | 1,2 | 3-200 | Any Direction | |||||||

| Noise Level | dB(A) | 1,2 | 3-200 | ≤58 | ≤59 | ≤62 | ≤65 | ≤68 | ≤69 | ≤70 |

Moment of Inertia

| Model No. | Unit | Stage | Ratio | PAD047 | PAD064 | PAD090 | PAD110 | PAD140 | PAD200 | PAD255 |

| Moment of Inertia | kg.cm2 | 1 | 4 | 0.03 | 0.14 | 0.48 | 2.74 | 7.54 | 23.67 | 54.37 |

| 5 | 0.03 | 0.13 | 0.47 | 2.71 | 7.42 | 23.29 | 53.27 | |||

| 7 | 0.03 | 0.13 | 0.45 | 2.62 | 7.14 | 22.48 | 50.97 | |||

| 10 | 0.03 | 0.13 | 0.44 | 2.57 | 7.03 | 22.51 | 50.56 | |||

| 2 | 12-40 | 0.03 | 0.03 | 0.13 | 0.47 | 2.71 | 7.42 | 23.29 | ||

| 50-100 | 0.03 | 0.03 | 0.13 | 0.44 | 2.57 | 7.03 | 22.51 |

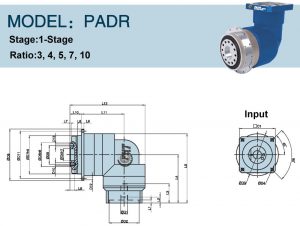

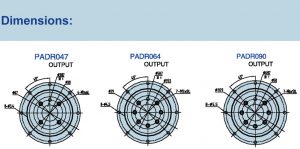

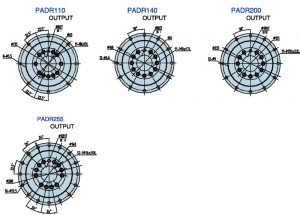

Reducer Dimensions:

(1) Single stage(Ratio: 3,4, 5, 7, 10)

Unit:mm

| Size | PAD047-L1 | PAD064-L1 | PAD090-L1 | PAD110-L1 | PAD140-L1 | PAD200-L1 | PAD255-L1 |

| D1 | 12 | 20 | 31.5 | 40 | 50 | 80 | 100 |

| D2 | 28 | 40 | 63 | 80 | 100 | 160 | 180 |

| D3 | 47 | 64 | 90 | 110 | 140 | 200 | 255 |

| D4 | 72 | 86 | 118 | 145 | 179 | 247 | 300 |

| D5 | ≤11/≤12 | 11(8-14) | 19(14-22) | 24(22-28) | 24(24-48) | 35(35-48) | 48(48-55) |

| D6 | 30 | 30(30-50) | 50(50-110) | 110 | 110(110-114.3) | 114.3(114.3-200) | 200 |

| D7 | 20 | 31.5 | 50 | 63 | 80 | 125 | 140 |

| D8 | 67 | 79 | 109 | 135 | 168 | 233 | 280 |

| D9 | Φ3 | Φ5XDep.8 | Φ6XDep.7 | Φ6XDep.7 | Φ8XDep.7 | Φ10XDep.10 | Φ12XDep.10 |

| D10 | 4-M3 | 7-M5XDep.8 | 8-M6XDep.12 | 11-M6XDep.12 | 11-M8XDep.17 | 11-M10XDep.20 | 12-M16XDep.25 |

| D11 | 8-Φ3.4 | 8-Φ4.5 | 8-Φ5.5 | 8-Φ5.5 | 12-Φ6.6 | 12-Φ9 | 16-Φ13.5 |

| D12 | 46 | 45(45-70) | 70(70-145) | 145 | 145(145-200) | 200(200-235) | 235 |

| D13 | M4 | M4-M5 | M5-M8 | M8 | M8-M12 | M12 | M12 |

| L1 | 3 | 3 | 6 | 6 | 6 | 8 | 12 |

| L2 | 7 | 7 | 10 | 10 | 14.5 | 15 | 21.5 |

| L3 | 4 | 4 | 7 | 8 | 10 | 12 | 18 |

| L4 | 19.5 | 19.5 | 30 | 29 | 38 | 50 | 66 |

| L5 | 4 | 8 | 12 | 13 | 12 | 16 | 20.0 |

| L6 | 3.5 | 4~5 | 5~10 | 10 | 6~8 | 6~10 | 10 |

| L7 | 30 | 28(28-34) | 32(32-59) | 60 | 73(73-115) | 88(88-117) | 119.5 |

| L8 | 70 | 80.5-87 | 97(97-120) | 142 | 159(159-201) | 196(196-229) | 255 |

| C1 | 48 | 60(40-60) | 90(60-130) | 130 | 130(130-180) | 180(180-220) | 220 |

Note 1:Inside of ()is the optional range of sizes,outside of ()is the standard sizes.

Note 2:The reducer output shaft size and length can be customized for customers.

Note 3:Input sizes can be subject to changed according to kinds of servo motor or stepper motor size.

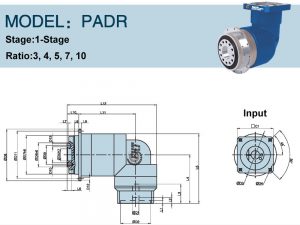

(2) Double stage(Ratio: 15,20,25,30,35,40,50,70,100)

unit:mm

| Size | PADR047-L2 | PADR064-L2 | PADR090-L2 | PADR110-L2 | PADR140-L2 | PADR200-L2 | PADR255-L2 |

| D1 | ≤11/≤12 | 11(11~14) | 19(19~24) | 24(22~32) | 32(24~35) | ≤48 | ≤55 |

| D2 | 30 | 50 | 70(70~110) | 110(110~130) | 110(110~114.3) | 85 | 116 |

| D3 | 46 | 70 | 90(90~145) | 145(145~165) | 145(145~200) | 215 | 235 |

| D4 | M4 | M4 | M8 | M8-M10 | M8-M12 | M12 | M12 |

| D5 | 12 | 20 | 31.5 | 40 | 50 | 80 | 100 |

| D6 | 28 | 40 | 63 | 80 | 100 | 160 | 180 |

| D7 | 47 | 64 | 90 | 110 | 140 | 200 | 255 |

| D8 | 72 | 86 | 118 | 145 | 179 | 247 | 300 |

| D9 | 20 | 31.5 | 50 | 63 | 80 | 125 | 140 |

| D10 | 4-M3 | 7-M5XDep.8 | 8-M6XDep.12 | 11-M6XDep.12 | 11-M8XDep.17 | 11-M10XDep.20 | 12-M16XDep.25 |

| D11 | 67 | 79 | 109 | 135 | 168 | 233 | 280 |

| D12 | 8-Φ3.4 | 8-Φ4.5 | 8-Φ5.5 | 8-Φ5.5 | 12-Φ6.6 | 12-Φ9 | 16-Φ13.5 |

| D13 | Φ3 | Φ5XDep.8 | Φ6XDep.7 | Φ6XDep.7 | Φ8XDep.7 | Φ10XDep.10 | Φ12XDep.10 |

| L1 | 3.5 | 5 | 12 | 10 | 8 | 6 | 6 |

| L2 | 8 | 10 | 13 | 19 | 17 | 20 | 24 |

| L3 | 30 | 32 | 42~47 | 57~60 | 67~77 | 85 | 116 |

| L4 | 74 | 80.5 | 107~112 | 134~147.5 | 166.5~167 | 213.5 | 268.5 |

| L5 | 103 | 115.5 | 152~157 | 195~208.5 | 217.5~241.5 | 269.5 | 340 |

| L6 | 4 | 8 | 12 | 13 | 12 | 22.5 | 30.5 |

| L7 | 3 | 3 | 6 | 6 | 6 | 8 | 12 |

| L8 | 7 | 7 | 10 | 11 | 15 | 15 | 20 |

| L9 | 4 | 4 | 7 | 8 | 10 | 12 | 18 |

| L10 | 19.5 | 19.5 | 30 | 29 | 38 | 50 | 66 |

| L11 | 79 | 94.5 | 117 | 163.5 | 187 | 243 | 270 |

| L12 | 122 | 149 | 187 | 253.5 | 300 | 382 | 403 |

| C1 | 48 | 60 | 90(90~130) | 130~160 | 130(130~220) | 190 | 220 |

Note 1:Inside of ()is the optional range of sizes,outside of ()is the standard sizes.

Note 2:The reducer output shaft size and length can be customized for customers.

Note 3:Input sizes can be subject to changed according to kinds of servo motor or stepper motor size.

Output dimension

Application

PADR series planetary reducers are widely used in manipulator, numerical control machine, cutting machine, numerical control pipe bending machine, textile machinery, painting machine, packaging machinery, medical equipment, welding machinery, printing equipment,etc.

Installation

(1)How to install the gearbox?

Step 1: Wipe off the anti-rust agent and grease on the motor shaft;

Step 2: Remove the rubber plug;

Step 3: Turn the input shaft until the cap screw is seen. Make sure the cap screw is loosened.

Step 4: Please place reducer vertically on a flat surface to make the surface of motor mounting upwards. Carefully insert motor shaft into the input shaft.( it should be inserted smoothly) Make sure the motor flange is perfectly fit to the reducer’s flange. Tighten the motor mounting bolt as per appointed fastening torque.

Step 5: Tightening the clamping bolt of input shaft with wrench according to the proper torque.

Step 6: Re-install the rubber plug. Finish the installation.

(2)How to store the reducer?

1)Keep the reducer in a clean and dry place.

2)If it will be stored outdoor or in a humid place, please put the reducer in a box and packed tightly with plastic bag to avoid the rain and external erosion. ( take measure of anti-condensation and anti-rust)

(3)Cautions for operation:

1)Please confirm the reducer model number confirm to the one you ordered when the reducer reach to you.

2)There is anti-rust agent on the reducer input and output shaft, please clean it before using.

3)Remove the rubber plug, wipe off the anti-rust agent.

4)The reducer was already filled with lubrication oil. You can use it right now.

5)When initial operation, please confirm the rotate direction of the output shaft, then increase the load little by little.

(4)Cautions during operation:

1)Overload is forbidden.

2)Input speed can not exceed the proper max. Speed.

3)Please stop and check the reducer if there are the following occurs:

Temperature rise suddenly

Abnormal big noise in a sudden

Speed became unstable suddenly

(5)Warranty instruction:

The following cost and damages are not included in our warranty:

1)Freight cost

2)If the Reducer connect with or insert in a unit, when we dismounting or mounting on the unit and other extra action, there will be a cost.( this is not contained in the warranty)

3)The indirect damage that user lost the appliance chance or business break off due to reducer breakdown.

4)Other derivative and accompanying damages.

Download

FAQ

1. What’s your delivery time?

Lead time: Normally 15-25 days after confirm your deposit. Products in stock will be delivered 3-5 days after your deposit.

2. What’s your MOQ?

MOQ is 1 PC

3. How long is your warranty?

Warranty: 1 year

4. Planetary gearbox can be customized?

Yes, please send your servo motor dimensions drawing.

5. Where is the gearbox manufactured?

Produced in Taiwan.

6. Your gearbox was ever shipped to which countries?

Our gearbox has been sold to various countries like Russia, Vietnam, Canada, Australia, UAE, Japan etc..

7. You are a factory or trading company?

We are factory, the manufacturer.