Features

AAW-P right angle spiral bevel gearbox is with one output shaft on left or right.Input side of AAW-P right angle servo gearbox is with motor adapter,which makes the mounted operation more easy without any extra installation accessories.

AAW-P series is the ideal option for the applicable transmission with limited space or needs to change the motion direction.AAW-P right angle 90 degree gearbox consists of stainless steel housing,spiral bevel gears and planetary unit with spur gears,so it is also called spiral bevel planetary gearbox.

AAW-P right angle gearbox have a variety of ratio from 1:2 to 1:300.The spiral bevel gearbox has a wide range of nominal torque 30Nm~4000Nm,suitable for different loads of the transmission system.

The spiral bevel gearbox has Ten sizes available: AAW080AS / AAW110AS / AAW135AS / AAW135BS / AAW165AS / AAW165BS / AAW200AS / AAW200BS/ AAW320AS / AAW320BS

Application

AAW-P 90 degree right angle gearbox is widely used in robot industry,pipe bending machine,stamping equipment,pulley,belt drives,printing machine,CNC machine,etc.

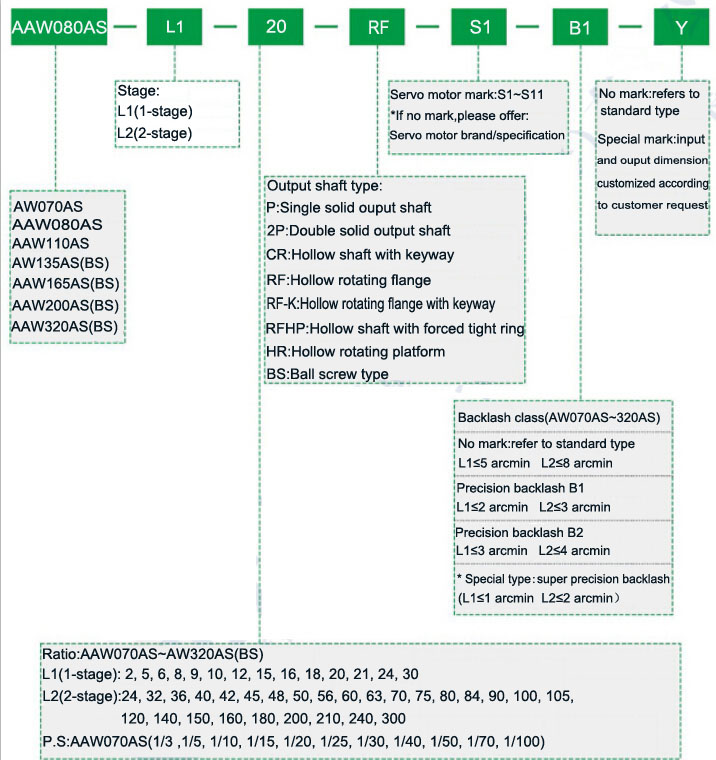

Model indication

Parameters

| Model No. | Stage | Ratio(i) | AAW080AS | AAW110AS | AAW135AS | AAW135BS | AAW165AS | AAW165BS | AAW200AS | AAW200BS | AAW320AS | AAW320BS |

| Rated Output Torque(Nm) | L1 | 2, 3, 5, 10 | 80 | 250 | 450 | * | 800 | * | 2000 | * | 3500 | * |

| 6 | 80 | 200 | 400 | 280 | 700 | 600 | 1500 | 1000 | 3500 | 2000 | ||

| 8 | 85 | 250 | 450 | 320 | 800 | 660 | 1850 | 1100 | 4000 | 2300 | ||

| 10 | 85 | 250 | 450 | 320 | 800 | 660 | 1850 | 1100 | 4000 | 2300 | ||

| 12 | 80 | 225 | 435 | 320 | 750 | 660 | 1850 | 1100 | * | 2300 | ||

| 14 | 80 | 215 | 425 | 280 | 750 | 600 | 1750 | 1000 | 3500 | 2200 | ||

| 16 | 80 | 210 | 415 | 270 | 700 | 600 | 1700 | 1000 | * | * | ||

| 20 | 70 | 200 | 400 | 240 | 700 | 460 | 1650 | 900 | 3000 | 1900 | ||

| L2 | 30 | 80 | 200 | 400 | 280 | 700 | 600 | 1500 | 1000 | 3500 | 2000 | |

| 32 | 85 | 250 | 450 | 320 | 800 | 660 | 1850 | 1100 | 4000 | 2300 | ||

| 40 | 85 | 250 | 450 | 320 | 800 | 660 | 1850 | 1100 | 4000 | 2300 | ||

| 50 | 85 | 250 | 450 | 320 | 800 | 660 | 1850 | 1100 | 4000 | 2300 | ||

| 56 | 85 | 250 | 450 | 320 | 800 | 660 | 1850 | 1100 | 3500 | 2300 | ||

| 60 | 80 | 200 | 400 | 280 | 700 | 600 | 1500 | 1000 | 3500 | 2000 | ||

| 70 | 85 | 250 | 450 | 320 | 800 | 660 | 1850 | 1100 | 3500 | 2200 | ||

| 80 | 85 | 250 | 450 | 320 | 800 | 660 | 1850 | 1100 | 3500 | 2300 | ||

| 100 | 85 | 250 | 450 | 320 | 800 | 660 | 1850 | 1100 | 3500 | 2300 | ||

| 120 | 80 | 225 | 435 | 290 | 750 | 630 | 1750 | 1050 | * | 2200 | ||

| 140 | 80 | 215 | 425 | 280 | 750 | 630 | 1750 | 1000 | 3200 | 2100 | ||

| 160 | 80 | 210 | 415 | 270 | 700 | 600 | 1700 | 950 | * | * | ||

| 200 | 70 | 200 | 400 | 240 | 700 | 460 | 1700 | 900 | 3000 | 1900 | ||

| Max. Output Torque(Nm) | L1,L2 | 3~100 | 2.5 Times of Normal Output Torque | |||||||||

| Input Speed(rpm) | L1,L2 | 3~100 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 |

| Standard Back-lash (arc-min) | L1 | 3~10 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 |

| L2 | 12~100 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | |

| Precision Backlash B2(arc-min) | L1 | 3~10 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 |

| L2 | 12~100 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | |

| Precision BacklashB1(arc-min) | L1 | 3~10 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 |

| L2 | 12~100 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | |

| Precision Backlash B0(arc-min) | L1 | 3~10 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

| L2 | 12~100 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | |

| Max. Radial Force(N) | L1,L2 | 3~100 | 3900 | 5500 | 9800 | 9800 | 16500 | 16500 | 24100 | 24100 | 35600 | 32600 |

| Max. Axial Force(N) | L1,L2 | 3~100 | 3900 | 5500 | 9800 | 9800 | 16500 | 16500 | 24100 | 24100 | 32600 | 32600 |

| Efficiency(%) | L1 | 3~10 | 90% | |||||||||

| L2 | 12~100 | 85% | ||||||||||

| Weight(kg) | L1 | 3~10 | 7.8 | 4.3 | 20.8 | 15.5 | 35.5 | 28.5 | 55 | 40.5 | 300 | 270 |

| L2 | 12~100 | 9.2 | 6.3 | 24.3 | 18.2 | 40.5 | 31.2 | 65.5 | 48.5 | 330 | 290 | |

| Operating Temp. | L1,L2 | 3~100 | -10℃~+80℃ | |||||||||

| Lubrication | L1,L2 | 3~100 | COMPLEX HV2 | |||||||||

| Mounting Position | L1,L2 | 3~100 | Any Direction | |||||||||

| Noise Level (db) | L1,L2 | 3~100 | ≤68 | ≤68 | ≤68 | ≤68 | ≤70 | ≤70 | ≤72 | ≤72 | ≤72 | ≤72 |

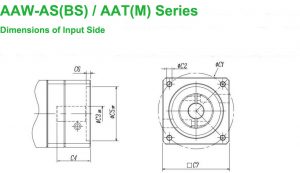

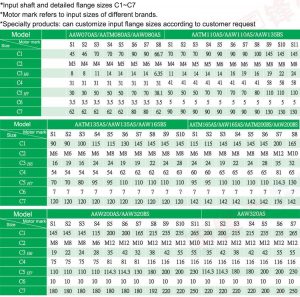

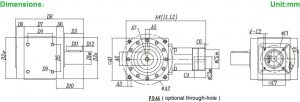

Dimensions

Input Sizes