Features

VRS series is a helical gear planetary gearbox,it has the below the feartures:

(1)Quiet operation

Helical gears contribute to reduce vibration and noise

(2)High precision

Standard backlash is arc-min,ideal for precision control

(3)High rigidity&torque

High rigidity&high torque were achieved by uncaged needle roller bearings

(4)Adapter-bushing connection

Can be attached to any motor all over the world

(5)No grease leakage

Perfect solution using high viscosity anti-separation grease.

(6)Maintenance-free

No need to replace the grease for the life of the unit.Can be attached in any position.

Guidelines

Before choosing a gearbox, please specify the gear ratio you need. After determine a ratio, multiplying your servo motor rated torque by the ratio, the value should be in principle less than our gearbox rated output torque which can be found int the data sheets. Take other overloads which drive the motor into consideration, to choose the max. Operating torque, this should not exceed 2 times of our gearbox rated torque.

After determine the above, you can choose a smallest volume gearbox to save cost.

You can send us the servo motor dimension drawing for model selection or advise the specific servo motor model number.

If you have special requirement for the precision, please clarify.

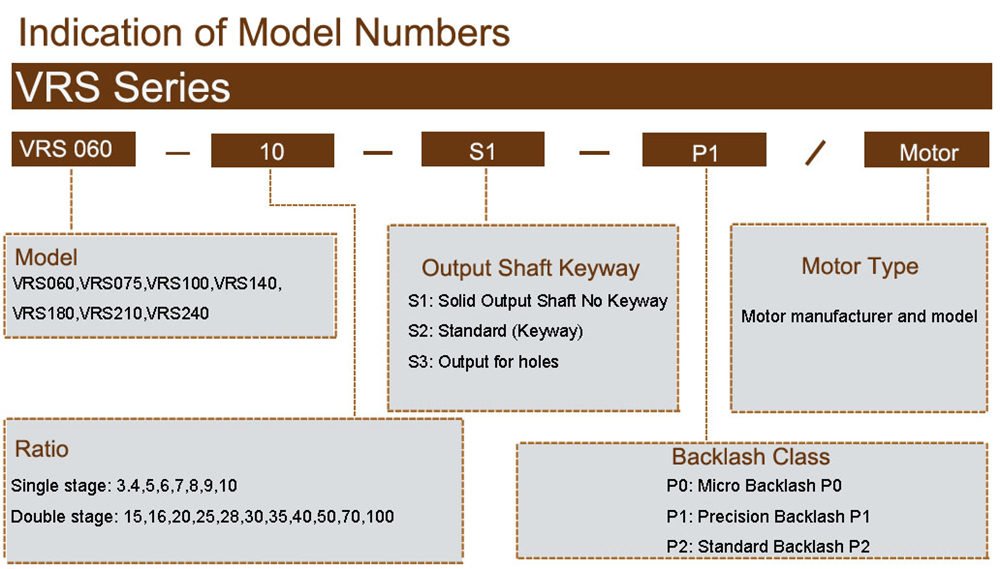

Indication

Parameters

| Model No. | Unit | Stage | Ratio | VRS060 | VRS075 | VRS100 | VRS140 | VRS180 | VRS210 | VRS240 |

| Rated Output Torque | Nm | 1 | 3 | 55 | 130 | 208 | 342 | 586 | 1140 | 1500 |

| 4 | 50 | 140 | 290 | 542 | 1050 | 1700 | 2500 | |||

| 5 | 60 | 160 | 330 | 650 | 1200 | 2000 | 2500 | |||

| 6 | 55 | 150 | 310 | 600 | 1100 | 1900 | 2260 | |||

| 7 | 50 | 140 | 300 | 550 | 1100 | 1800 | 2300 | |||

| 8 | 45 | 120 | 260 | 500 | 1000 | 1600 | 2100 | |||

| 9 | 40 | 100 | 230 | 450 | 900 | 1500 | 1800 | |||

| 10 | 40 | 100 | 230 | 450 | 900 | 1500 | 1800 | |||

| 2 | 15 | 55 | 130 | 208 | 342 | 586 | 1140 | 2300 | ||

| 16 | 55 | 130 | 208 | 342 | 586 | 1140 | 2300 | |||

| 20 | 50 | 140 | 290 | 542 | 1050 | 1700 | 2500 | |||

| 25 | 60 | 160 | 330 | 650 | 1200 | 2000 | 2500 | |||

| 28 | 60 | 160 | 330 | 650 | 1200 | 2000 | 2500 | |||

| 30 | 55 | 150 | 310 | 600 | 1100 | 1900 | 2300 | |||

| 35 | 50 | 140 | 300 | 550 | 1100 | 1800 | 2200 | |||

| 40 | 45 | 120 | 260 | 500 | 1000 | 1600 | 2350 | |||

| 50 | 60 | 160 | 330 | 650 | 1200 | 2000 | 2200 | |||

| 70 | 50 | 140 | 300 | 550 | 1100 | 1800 | 2200 | |||

| 100 | 40 | 100 | 230 | 450 | 900 | 1500 | 1800 | |||

| Max. Output Torque | Nm | 1,2 | 3-100 | 3 Times of Normal Output Torque | ||||||

| Rated Input Speed | Rpm | 1,2 | 3-100 | 5000 | 4000 | 4000 | 3000 | 3000 | 2000 | 1000 |

| Max. Input Speed | Rpm | 1,2 | 3-100 | 10000 | 8000 | 8000 | 6000 | 6000 | 4000 | 2500 |

| Micro Backlash P0 | Arcmin | 1 | 3-10 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

| 2 | 12-100 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| Precision Backlash P1 | Arcmin | 1 | 3-10 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 |

| 2 | 15-100 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ||

| Torsional Rigidity | Nm/arcmin | 1,2 | 3-100 | 7 | 14 | 25 | 50 | 145 | 225 | 260 |

| Max. Radial Force | N | 1,2 | 3-100 | 2750 | 4100 | 6400 | 9880 | 15000 | 20000 | 27500 |

| Max. Axial Force | N | 1,2 | 3-100 | 2350 | 3200 | 5360 | 9690 | 14200 | 28000 | 30000 |

| Service Life | Hr | 1,2 | 3-100 | 20000hrs | ||||||

| Efficiency | % | 1 | 3-10 | ≥96% | ||||||

| 2 | 15-100 | ≥93% | ||||||||

| Weight | Kg | 1 | 3-10 | 1.8 | 3.8 | 7.2 | 16.8 | 32 | 49 | 65 |

| 2 | 15-100 | 2.1 | 4.1 | 8.1 | 17.5 | 35 | 53 | 70 | ||

| Operating Temperature | ℃ | 1,2 | 3-100 | (-15℃~+90℃) | ||||||

| Lubrication | 1,2 | 3-100 | Synthetic Grease | |||||||

| Protection Class | 1,2 | 3-100 | IP65 | |||||||

| Mounting Position | 1,2 | 3-100 | Any Direction | |||||||

| Noise Level | dB(A) | 1,2 | 3-100 | ≤62 | ≤62 | ≤65 | ≤68 | ≤68 | ≤70 | ≤70 |

Moment of Inertia

| Model No. | Unit | Stage | Ratio | VRS060 | VRS075 | VRS100 | VRS140 | VRS180 | VRS210 | VRS240 |

| Moment of Inertia | kg.cm2 | 1 | 3 | 0.16 | 0.61 | 3.25 | 9.21 | 28.98 | 69.61 | 82.16 |

| 4 | 0.14 | 0.48 | 2.74 | 7.54 | 23.67 | 54.37 | 75.58 | |||

| 5 | 0.13 | 0.47 | 2.71 | 7.42 | 23.29 | 53.27 | 75.29 | |||

| 6 | 0.13 | 0.45 | 2.65 | 7.25 | 22.75 | 51.72 | 72.35 | |||

| 7 | 0.13 | 0.45 | 2.62 | 7.14 | 22.48 | 50.97 | 69.13 | |||

| 8 | 0.13 | 0.44 | 2.58 | 7.07 | 22.59 | 50.84 | 69.22 | |||

| 9 | 0.13 | 0.44 | 2.57 | 7.04 | 22.53 | 50.63 | 66.23 | |||

| 10 | 0.13 | 0.44 | 2.57 | 7.03 | 22.51 | 50.56 | 66.23 | |||

| 2 | 15-40 | 0.03 | 0.13 | 0.47 | 2.71 | 7.42 | 23.29 | 48.23 | ||

| 50-100 | 0.03 | 0.13 | 0.44 | 2.57 | 7.03 | 22.51 | 45.58 |

Reducer Dimensions:

(1) Single stage(Ratio:3,4, 5,7,10)

Unit:mm

| Size | VRS060-L1 | VRS075-L1 | VRS100-L1 | VRS140-L1 | VRS180-L1 | VRS210-L1 | VRS240-L1 |

| D1 | Φ16 | Φ22 | Φ32 | Φ40 | Φ55 | Φ75 | Φ85 |

| D2 | Φ60 | Φ70 | Φ90 | Φ130 | Φ160 | Φ180 | Φ200 |

| D3 | Φ8(8-19) | Φ14(14-24) | Φ19(19-35) | Φ24(24-48) | Φ38(38-48) | Φ48(48-55) | Φ60 |

| D4 | Φ30(30-70) | Φ50(50-110) | Φ70(70-114.3) | Φ110(110-114.3) | Φ114.3(114.3-200) | Φ200 | Φ220 |

| D5 | Φ68 | Φ85 | Φ120 | Φ165 | Φ215 | Φ250 | Φ290 |

| D6 | 4-Φ5.5 | 4-Φ6.6 | 4-Φ9 | 4-Φ11 | 4-Φ13.5 | 4-Φ17 | 4-Φ17 |

| D7 | Φ46(45-90) | Φ70(70-145) | Φ90(90-200) | Φ145(145-200) | Φ200(200-235) | Φ235 | Φ240 |

| D8 | M3-M5 | M4-M8 | M5-M12 | M8-M12 | M12 | M12 | M16 |

| D9 | M5 | M8 | M12 | M16 | M20 | M20 | M20 |

| L1 | 28 | 36 | 58 | 82 | 82 | 105 | 130 |

| L2 | 5 | 6 | 8 | 10 | 12 | 15 | 20 |

| L3 | 6 | 7 | 10 | 12 | 15 | 17 | 20 |

| L4 | 48 | 56 | 88 | 112 | 112 | 143 | 170 |

| L5 | 7.5~9 | 10.5~16 | 12~36.5 | 8 | 10 | 10 | 12 |

| L6 | 42~43.5 | 50.5~66 | 62~82 | 69~115 | 83~117 | 116 | 55 |

| L7 | 94.5~96 | 117.5~133 | 139~153 | 170~216 | 210~244 | 257 | 295 |

| L8 | 142.5~144 | 173.5~189 | 227~247 | 282~328 | 322~356 | 400 | 465 |

| C1 | □60 | □75 | □100 | □140 | □182 | □215 | □240 |

| C2 | 40(40-80) | 60(60-130) | 80(80-180) | 130(130-180) | 180(180-220) | 220 | 250 |

| S1 | 2 | 3 | 10 | 5 | 6 | 7 | 3 |

| S2 | 22 | 28 | 40 | 70 | 70 | 90 | 105 |

| S3 | 18 | 24.5 | 35 | 43 | 59 | 79.5 | 90 |

| B | 5 | 6 | 10 | 12 | 16 | 20 | 22 |

Note 1:Inside of ()is the optional range of sizes,outside of ()is the standard sizes.

Note 2:The reducer output shaft size and length can be customized for customers.

Note 3:Input sizes can be subject to changed according to kinds of servo motor or stepper motor size.

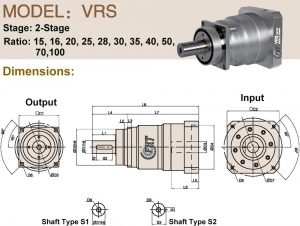

(2) Double stage(Ratio: 15,16,20,25,28,30,35,40,50,70,100)

unit:mm

| Size | VRS060-L2 | VRS075-L2 | VRS100-L2 | VRS140-L2 | VRS180-L2 | VRS210-L2 | VRS240-L2 |

| D1 | Φ16 | Φ22 | Φ32 | Φ40 | Φ55 | Φ75 | Φ85 |

| D2 | Φ60 | Φ70 | Φ90 | Φ130 | Φ160 | Φ180 | Φ200 |

| D3 | Φ8(8-14) | Φ14(14-24) | Φ19(19-28) | Φ24(24-38) | Φ38(24-42) | Φ48(48-55) | Φ48 |

| D4 | Φ30(30-50) | Φ50(50-110) | Φ50(50-110) | Φ110(110-114.3) | Φ114.3(110-114.3) | Φ200 | Φ220 |

| D5 | Φ68 | Φ85 | Φ120 | Φ165 | Φ215 | Φ250 | Φ290 |

| D6 | 4-Φ5.5 | 4-Φ6.6 | 4-Φ9 | 4-Φ11 | 4-Φ13.5 | 4-Φ17 | 4-Φ17 |

| D7 | Φ46(45-70) | Φ70(70-145) | Φ70(70-200) | Φ145(145-200) | Φ200(200-235) | Φ235 | Φ240 |

| D8 | M3-M5 | M4-M8 | M5-M8 | M8-M12 | M8-M12 | M12 | M16 |

| D9 | M5 | M8 | M12 | M16 | M20 | M20 | M20 |

| L1 | 28 | 36 | 58 | 82 | 82 | 105 | 130 |

| L2 | 5 | 6 | 8 | 10 | 12 | 15 | 20 |

| L3 | 6 | 7 | 10 | 12 | 15 | 17 | 20 |

| L4 | 48 | 56 | 88 | 112 | 112 | 143 | 170 |

| L5 | 8~9 | 10.5~16 | 12~18.5 | 6~8 | 6~10 | 10 | 12 |

| L6 | 42~43.5 | 50.5~66 | 61~68 | 69~81 | 69~117 | 116 | 55 |

| L7 | 116.5~117.5 | 143~158.5 | 172~178 | 210~222 | 236.5~293.5 | 257 | 346 |

| L8 | 164.5~165.5 | 199~214.5 | 260~266 | 322~334 | 348.5~406.5 | 400 | 516 |

| C1 | □60 | □75 | □100 | □140 | □182 | □215 | □240 |

| C2 | 40(40-65) | 60(60-130) | 60(60-130) | 130(130-180) | 130(130-180) | 220 | 250 |

| S1 | 2 | 3 | 10 | 5 | 6 | 7 | 3 |

| S2 | 22 | 28 | 40 | 70 | 70 | 90 | 105 |

| S3 | 18 | 24.5 | 35 | 43 | 59 | 79.5 | 90 |

| B | 5 | 6 | 10 | 12 | 16 | 20 | 22 |

Note 1:Inside of ()is the optional range of sizes,outside of ()is the standard sizes.

Note 2:The reducer output shaft size and length can be customized for customers.

Note 3:Input sizes can be subject to changed according to kinds of servo motor or stepper motor size.

Characteristics

(1)Gears: with helical gear design, the gear meshing rate is more than twice the normal gear, with smooth running, low noise,high output torque, and low backlash. The gears adopt special grease lubrication and IP65 protection grade seal design, the output shaft surface is of polishing treatment, and adopt reasonable tolerance. Ensure minimum friction coefficient and reduce startup load. No oil leakage or maintenance in service life in any direction.

(2)Output planet rack: the planetary arm frame and the output shaft adopt integrated design. Before and after bearing large span is distributed in the box body, forming a stable one-piece structure. Ensure high torsion stiffness and accuracy. Adjust the axial clearance through the adjustment sleeve on the planetary shelf.

(3)Output inner ring: the tooth ring and the output side shell adopts the integral design, adopt the high quality steel, through hot forging forming, thus obtain the higher material density. The integrated design ensures that all geometric dimensions are processed at one time, with higher precision and strength than other embedded and clamped structures.

(4)Input shaft:input shaft and the locking device adopts integrated design, double bolt symmetric distribution, to achieve the dynamic balance at the same time, through double bolt strong lock, effectively prevent motor shaft driving sliding, achieve high accuracy zero back power transmission.

(5)Install flange:advanced connecting plate design, easy to install with various factory brand servo, stepping motor perfectly.

Application

VRS series planetary reducers are widely used in Printer, Belt Conveyer, Gantry Robot, Auto packing sealing machine, Packing machine ( vertical pillow), Packing machine ( horizontal pillow), Dispenser Robot, Loader robot etc.

Installation

(1)How to install the gearbox?

Step 1: Wipe off the anti-rust agent and grease on the motor shaft;

Step 2: Remove the rubber plug;

Step 3: Turn the input shaft until the cap screw is seen. Make sure the cap screw is loosened.

Step 4: Please place reducer vertically on a flat surface to make the surface of motor mounting upwards. Carefully insert motor shaft into the input shaft.( it should be inserted smoothly) Make sure the motor flange is perfectly fit to the reducer’s flange. Tighten the motor mounting bolt as per appointed fastening torque.

Step 5: Tightening the clamping bolt of input shaft with wrench according to the proper torque.

Step 6: Re-install the rubber plug. Finish the installation.

(2)How to store the reducer?

1) Keep the reducer in a clean and dry place.

2) If it will be stored outdoor or in a humid place, please put the reducer in a box and packed tightly with plastic bag to avoid the rain and external erosion. ( take measure of anti-condensation and anti-rust)

(3)Cautions for operation:

1) Please confirm the reducer model number confirm to the one you ordered when the reducer reach to you.

2) There is anti-rust agent on the reducer input and output shaft, please clean it before using.

3) Remove the rubber plug, wipe off the anti-rust agent.

4) The reducer was already filled with lubrication oil. You can use it right now.

5) When initial operation, please confirm the rotate direction of the output shaft, then increase the load little by little.

(4)Cautions during operation:

1) Overload is forbidden.

2) Input speed can not exceed the proper max. Speed.

3) Please stop and check the reducer if there are the following occurs:

Temperature rise suddenly

Abnormal big noise in a sudden

Speed became unstable suddenly

(5)Warranty instruction:

The following cost and damages are not included in our warranty:

1) Freight cost

2) If the Reducer connect with or insert in a unit, when we dismounting or mounting on the unit and other extra action, there will be a cost.( this is not contained in the warranty)

3) The indirect damage that user lost the appliance chance or business break off due to reducer breakdown.

4) Other derivative and accompanying damages.

Download

FAQ

1. What’s your delivery time?

Lead time: Normally 15-25 days after confirm your deposit. Products in stock will be delivered 3-5 days after your deposit.

2. What’s your MOQ?

MOQ is 1 PC

3. How long is your warranty?

Warranty: 1 year

4. Planetary gearbox can be customized?

Yes, please send your servo motor dimensions drawing.

5. Where is the gearbox manufactured?

Produced in Taiwan.

6. Your gearbox was ever shipped to which countries?

Our gearbox has been sold to various countries like Russia, Vietnam, Canada, Australia, UAE, Japan etc..

7. You are a factory or trading company?

We are factory, the manufacturer.